The CQM (Automatic Heat Exchangers Cleaning System) was finally mounted on refrigerated water compressor 3#, in May 27, 2004, for the refrigerator room of Haizhu Square Subway Station in Guangzhou, and had been put into operation in May 28, the same year. Up till now, namely, August 18, 2004, it has served in safe operation for 80 days, during which the CQM has reached desired result.

1. Solution has been eventually found for clogging of condenser by silt from Zhujiang River.

Ever from the first day of operation, the temperature difference of heat transfer in condensers has been increasing quite slowly. Until now, the

temperature difference is still kept at 2.1oC (condenser 1#) and 2.30C (condenser 2#), about which, however, apparent temperature rises still exist

in two phases.

- During the first month of operation, inlet valve has always been opened

by 1/3 to activate water pump 3#, due to the relatively low water temperature

of the Zhujiang River, thus the performance in cleaning CQM was somewhat

affected. - Around 45th day since operation started, the reduced filtering

performance of water intake made cooling water pump partly clogged,

resulting in volume reduction of cooling water, which finally influenced the

cleaning of CQM. However, after the cooling water volume was further

stabilized, CQM went again into normal operation.

2. Heat exchange rate of condensers has been enhanced by solving the clogging, achieving high energy conservation.

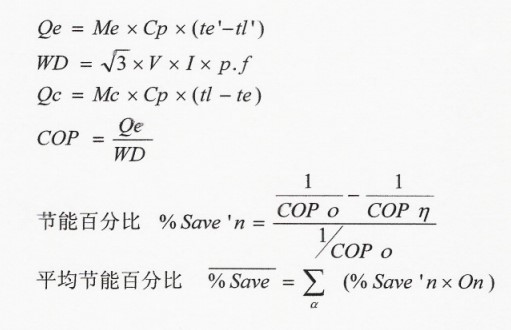

After 45 days of safe operation, the performance in energy saving of CQM was tested, about which comparison had been made for one month with the refrigerated water compressor 1# with no CQM installed. As a result, 2 scientific calculation result has shown CQM saved energy significantly.

1) Comparison between Temperature Differences of Condensers’ heat transfer

The 2 refrigerated water compressors, from July 15 to August 11, had been basically set into full capacity (the preparation for compressor 1# was just completed

in July 14, and the temperature differences of heat transfer for condensers 1# and 2#, in that period, stood at 1.0 and 1.1,respectively).

2) Comparison of COPs and energy saving ratio.

According to recording, comparison has been made on the working parameters of one month for refrigerated water compressors 1# and 3#, and facts have shown that the average energy saving ratio of compressor 3#, on which CQM has been mounted, stood at 17.21% against the compressor 1# with no such facility installed.

3) Return on Investment

- Power charge saved

Daily power consumption saved by compressor 3#:

568*75%*12*17.21%=879.77kwhlday (12 hours per day)

Annual power consumption saved:

879.77*30*6=158,358.6kwh (6 months per year)

Annual power charge saved:

158,358.6*0.72=114,018.19RMB (0.72RMB/kwh for unit cost) - Cleaning charge saved: 2,500RMBlset*year

CQM features high return on investment, according to the recording, and the capital will be recouped in less than three years.

4) Introduction of applying CQM in the system

- Application and wearing of the balls

The key technique of CQM lays on the balls which are to solve the clogging in condenser. During three days since initial running, 22~28 balls will fail in recycling because of the blind zone, dead space, the positioning on cap of end socket, etc. in the system. However, after these three days’ stabilizing, remained balls will achieve 100% recovery.

Ball feeding valve, during operation, would cut up 2~3 balls monthly, which phenomenon isjust a normal loss. - Adjusting technical parameters during application

According to performance in conventional systems, it is recommended that the amount of balls account for 40% of that of condenser tubes. However, we have adjusted the amount of balls, in practical utilization, which is defined at 100% for better performance in this system.

With respect to the timing on ball feeding and return, we have also partly adjusted the parameters set during initial operation, according to long period of observation.