Maintaining Heat Exchanger Tubes Clean

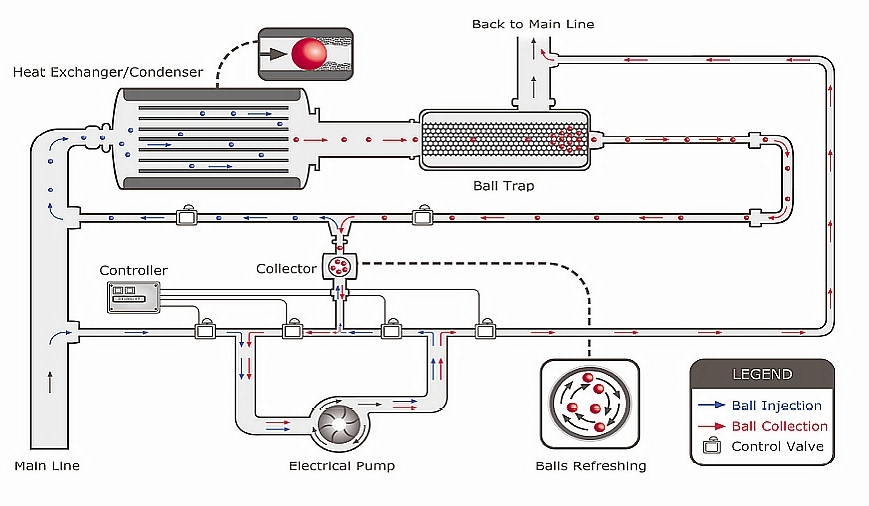

ATCS-Industrial conserves the heat exchange efficiency of tube and shell heat exchangers by maintaining the exchanger tubes free of fouling. Rubber balls are recirculated at set time intervals to capture deposits accumulated in the heat exchanger tubes.

ATCS-Industrial reduces plant downtime and optimizes efficiency

ATCS is the most efficient automatic on-line solution for keeping heat exchanger tubes continuously clean and providing optimal heat exchange:

- Maintains process efficiency by optimizing the heat transfer capacity of heat exchangers.

- Increases plant productivity by preventing stoppage days otherwise required for manual cleaning of the tubes

How ATCS Works

The CQM ATCS is installed on steam condensers and keeps tubes clean without human intervention. The system periodically injects into the tubes sponge balls that are slightly larger in diameter then the tubes themselves. The natural pressure head pushes the balls through the tube, which is thus rubbed clean. The balls are then trapped in the outlet of the condenser, where they are prepared for the next cleaning cycle.

Typical industrial installations take less than 50 man hours, and require only a few hours of process shutdown.

Trapping units are available in a variety of shapes and flow configurations to accommodate piping routes design and available space for installation

[smart-grid row_height=”320″ style=”12″ captions_color=”#ffffff” captions_opacity=”0.8″ font_family=”agenda-light” google_font=”agenda-light” font_color=”#000000″ lightbox=”magnific-popup”]

CQM ATCS’ Main Advantages

- Excellent cleaning: reaches all tubes, both central and peripheral.

- Simple design: delivering high reliability, rapid installation, and effortless maintenance.

- Wide range of sizes: suitable for a wide variety of heat exchangers.

- Better ball trapping mechanism: absolutely no balls lost.

- Accurate control of the cleaning process: customizable cleaning intervals provide high performance and minimize balls’ wear.

CQM ATCS Benefits

- Tubes are kept clean at all times.

- Heat exchanger constantly works at maximum efficiency.

- No downtime for periodic maintenance

- No chemicals and residues disposal hassle.

- Simple maintenance through continuous, automatic cleaning.

- Extends system service period.

- Innovative design delivers high reliability and simple integration.

ATCS vs. Manual Off-line Cleaning

CQM ATCS

Continuously operating

at maximum efficiency.

MANUAL OFF-LINE CLEANING

Performance gradually

decreases between treatments.

CQM ATCS

No shutdown normally.

On-line cleaning.

MANUAL OFF-LINE CLEANING

Requires shutdown for cleaning.

CQM ATCS

No chemicals.

No residues.

MANUAL OFF-LINE CLEANING

Cleaning chemicals & residues

harmful to environment.

CQM ATCS

Fully automatic.

Effortless maintenance.

MANUAL OFF-LINE CLEANING

High due to performance

monitoring & manual cleaning.

Downloads

![]() Brochure

Brochure

![]() Description and Data Sheet

Description and Data Sheet

![]() RFI/RFQ Questionnaire

RFI/RFQ Questionnaire

The majority of people are trying to find the top essay writing service. There are some things you have to consider buy an essay online reviews prior to purchasing an essay writing service. Prior to purchasing from a company be aware of these: