How Does Condenser Cleaner Works?

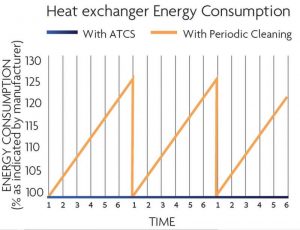

Periodic online condenser cleaners, heat exchangers and chillers ensure that the heat exchange is optimized and that there is no energy loss. However, since fouling starts as soon as the cleaning is performed, energy loss -represented by the areas under the triangles in the picture – is inevitable. Depending on the type of the system, energy losses due to fouling can average up to 30%. The ATCS inline cleaning system prevents this energy loss, and usually pays for itself in less than two years.

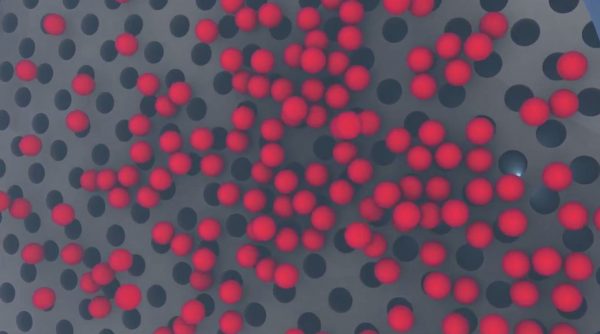

ATCS-HVAC conserves the heat exchange efficiency of condenser tubes of water cooled air conditioning chillers by maintaining the condenser tubes free of fouling. Rubber balls are recirculated at set time intervals to prevent deposits accumulation in the condenser tubes and run online condenser cleaning.

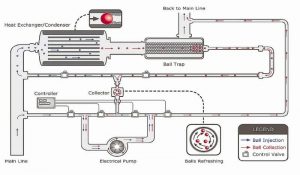

Ball collector holds the balls between the cleaning cycles, where they are rinsed.

All of the balls are injected at once at given periods. This makes sure that they penetrate all of the pipes and that all of the pipes are maintained clean.

A grid like ball trap without any moving parts ensures that no balls are lost – ever.

The principle of operation is shown in the following animation

The CQM ATCS is installed on steam condensers and keeps tubes clean from dirt and debris without human intervention. The system periodically injects into the tubes sponge balls that are slightly larger in diameter then the tubes themselves. The natural pressure head pushes the balls through the tube, which is thus rubbed clean. The balls are then trapped in the outlet of the condenser, where they are prepared for the next cleaning cycle.

Typical comercial installations take less than 25 man hours, and requires only 8 hours of process shutdown. Trapping units are available in a variety of shapes and flow configurations to accommodate piping routes design and available space for installation.

ADVANTAGES OF ATCS-HVAC OVER CONVENTIONAL SYSTEMS

- Cost-effective: maximizes chiller efficiency for multiplied savings in operation, manpower and energy – up to 25% savings in the chiller’s annual operation cost.

- Environmentally safe: uses no chemicals, produces no hazardous waste.

- Continual operation: works while the air conditioning system is on.

- Automatic: computer-timed cleaning with no need for intervention.

- Reliable: high-performance parts.

- Efficient: one ATCS-HVAC installation can handle an entire facility.

- Measurable savings: reliably measure savings with installation of the optional Integrated Performance Tracker.

A turnkey solution – installed with minimal disruption

- The ATCS-HVAC integrates easily with any existing HVAC.

- Installation takes place while the HVAC is online, with only a brief shut-down to assemble the ball-trap unit and create the ball-injection opening.

- No need for ball-guiding vanes on the condenser inlet nozzle.

- Installed and operational in just a few hours.

ATCS-HVAC installations are operating in thousands of facilities, in dozens of countries around the world

- Office complexes

- Office complexes

- Hotels

- Hospitals

- Industrial refrigerators

- Industrial room control systems

Downloads